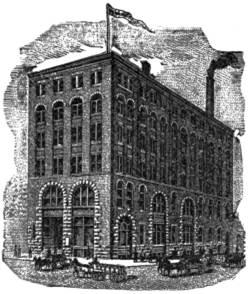

Brigham, Hopkins & Co. Factory and Salesroom

419 West Redwood Street

Baltimore, Maryland

Year Built: 1884

Brigham, Hopkins & Co. was a manufacturer of straw hats located in Baltimore. One of its principals was William T. Brigham, a step-brother of architect Charles Brigham. This business was very successful and the firm had built a number of buildings and additions that housed it.

Ground was broken for the building at 419 West Redwood Street at the corner of South Paca Street, in April, 1884, and was completed and occupied in January, 1885. It had a frontage of forty-one feet six inches on West Redwood Street, and extends back on Paca Street one hundred and fifty feet to Cider Alley. In 1900, an addition was added on the east side, replicating all of the design elements of the original building and almost doubled the amount of space of the building. This addition was so well designed that it looks seamless.

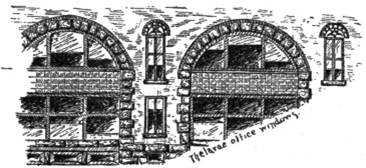

The building rises six stories and is constructed of Baltimore pressed brick and Potomac red sandstone. The ornamentation surrounding the windows is of terra-cotta and molded brick. The style of the building is Romanesque with round arches. Very striking features are the immense arched openings upon the Paca Street façade, being seventeen feet in width and twenty-five feet in height, which with their broad treatment of mullioned panels and heavy rough-hewn stonework, give strength and character to the building. These spacious windows were not simply for effect, but designated the location of the principal offices, and by their wide expanse provided abundant light to the then show-rooms. Indeed, the number of windows over the entire structure was intended to provide a substantial measure of light.

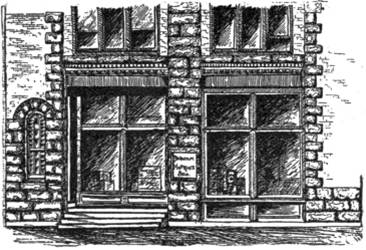

At the main entrance, a slight elevation was made from the sidewalk, and beyond a recess of several feet were framed two large French plate glass windows, which afforded a view of the entire extent of the first floor. The entrance doors were placed on either side of this recess.

Upon entering the building, a person would have seen offices for the members of the firm, clerical employees as well as the show-rooms for the exhibit of the products of this factory. Separating these functions was a series of beaded cherry partitions and the rooms themselves in solid cherry to harmonize with the color of the exterior.

In the first office was a fire-proof vault, having a counterpart in size in the basement, upon which the one in the office rests; it was built of yellow enameled-face brick, and with a finished iron door surmounted with a bold decoration in terra-cotta, adding significantly to the ornamentation of this room.

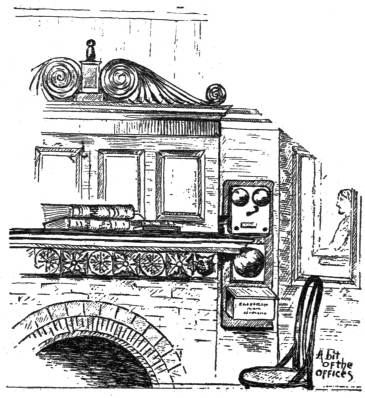

Adjoining was the private office of the members of the firm; among the decorations of this room was a spacious open fire-place, ornamented with terra-cotta tile and a handsome mantelpiece in carved cherry. Beyond and leading from this office were show-rooms for the exhibition of the firm's products. These two show-rooms (the first was 25x18 feet and the second was 18x12 feet), were furnished with show-cases of solid cherry and glass; the wall space was colored a light tint, while the ceilings were in yellow and brown. A long table composed of solid cherry occupied the center of the large room, while the hard-wood floors were partially covered with oriental rugs.

Beyond the show-rooms was a store room used to collect “hat trimmings,” the ornamental bands made of varying materials placed above the brim. After this room was a packing and shipping area

On the second floor was the "finishing" department of the firm and it occupied the entire floor.

The third floor housed three departments: silk and felt hat trimming, straw hat trimming and the printing department.

On the fourth floor was the sewing department, the winding and reeling department and the machine room, which housed broken machinery, in the process of being repaired.

The fifth floor housed the straw hat pressing department.

On the sixth floor was the finishing department, composed of a large room 150 x 25 feet, surrounded on three sides by windows to provide the maximum light for the workers. Adjoining this large room was bleaching and dying department.

Ascending still another flight of stairs, the drying department is reached; this is the most spacious of all the many divisions of this establishment, for it has the sky for a ceiling and unlimited space, being virtually upon the roof. Here, ninety feet from the ground, is carried on one of the important divisions of the straw hat business. Two large rooms, really houses in themselves, are built upon this roof; these are the bleach houses, which are provided with artificial stone floors, rendering them thoroughly secure from the chance of ignited brimstone coming in contact with any part of the woodwork of the building. The remaining space upon the roof, equal in its extent to two good-sized city building lots, is secured around and over by a substantial wire netting. Within this enclosure the hats and straw braids coming from the bleaching and dyeing departments are dried.

A stairway led from the first floor from the front end of the building and there was also a stairway in the rear end as well.

A separate boiler house was built on the east side of building, separated by a fire-proof brick wall, and was accessible by entrance from the outside. Above this boiler-room are the molding and casting departments. This building was likely demolished in 1900 to make way for the large addition.

Two large freight elevators, reaching from basement to roof, each of one ton capacity and propelled by steam power, were in the building. These elevators are furnished with automatic attachments by which as they ascend and descend each of the floors open and close, thus avoiding permanent openings, the frequent cause of accidents and assistance in the spread of a conflagration; an additional small elevator gives the convenience of transmitting light packages to and from every floor.

Electric bells and tubes afforded telephonic communication with every department. Steam heat radiated throughout the entire building, and a reel of hose attached to a water supply pipe was installed in case of fire. The length of steam, gas, and water pipes throughout the building was estimated at five miles. The telegraph call-box signaled for the messenger, and the telephone, aided in the execution of the advanced method of reducing the detailed requirements of a large business to a perfectly controllable system in its management.

The engine supplying the motive power for the establishment was located in the basement. With exception of this room, partitioned off for the engine, the entire space of the basement was used for receiving and storing raw materials used in the manufacture of both straw and fur hats.

Although there is no documentary evidence that this building was designed by Charles Brigham, it is known that Charles and his step brother William had a very close relationship and William called this building a “design . . . one of the handsomest of its kind in the country . . . .” Most likely a nod to his brother. There are also a number of elements the Brigham commonly used in other designs. For example, the hood above the main entrance looks the same as the one he used on the Mass. State House extension and for Watertown Savings Bank.

In 2013, the building is the University of Maryland Professional Building.

References

• Brigham, William T., "Baltimore Hats: Past and Present," Baltimore, 1890

Links

• http://www.davidjrusso.com/architecture/brigham/buildings/AddressSummary.php?id=13600064300118

Images

1889, illustration of the exterior

Details

1889, illustration of window detail

Above the front door, indicating the dates of construction of the original and addition.

1889, illustration of the front entrance

2018, South Paca Street facade, corner of West Redwood Street

2018, South Paca Street facade, corner of Cider Alley

Detail

2018, view of rear from Cider Alley. The 1884 portion is the left 2/3 of the facade.

1889, illustration of mantle, fireplace and surround

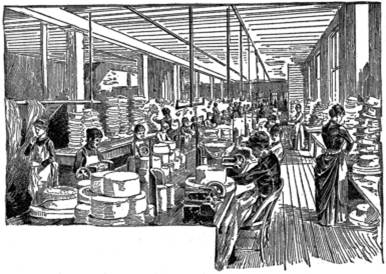

1889, illustration of sewing room

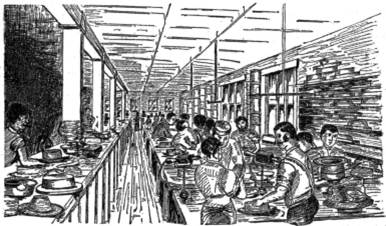

1889, illustration of straw hat finishing department

<<< Back to Design List

|

|

|